Mercy Hill Farm Barn Remodel 2020

This is the front of the barn at the beginning of summer 2020. The siding had become unsalvageable and the glass panes were falling out of the window sashes. Worse yet, the paved driveway was installed right up against the siding, which rotted out the siding, the interior wall boards, the sill and much of the bottom 3 to 6 feet of the frame posts.

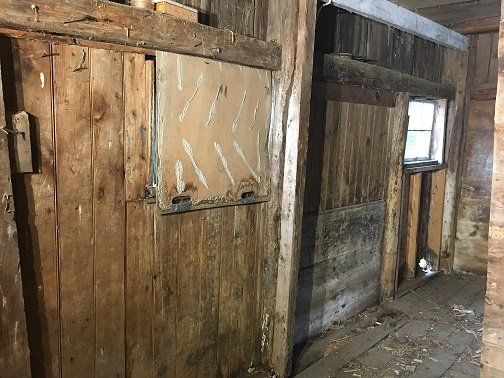

exterior water damage and rot

Removing the siding where the asphalt butts right up against the wooden wall reveals a terrible mistake. Because of the asphalt being poured right up against the wooden wall, the entire lower 3 feet or so of the barn was destroyed by water damage.

the "floors"

I use this term loosely. These were floors, in an academic sense I guess.

demolition

restoration planning

Once all the wall boards were removed we could see the beautiful old hand hewn eastern white pine post and beam frame. The fact that it was still standing, despite every post on this side being rotted 2 to 3 feet up is an incredible testimony to the early craftsmen who built the original barn.

Under 6 or 7 layers of "flooring" the support joists were completely detached from the rotted out sill.

The floor was the most difficult part of the demo.

Layer after layer of boards were nailed together with rotted wood in between. When you try to pry one layer away from another, the pry bar would just sink into the rot. Finally, we had to cut each section away a little at a time with a long bladed reciprocating saw.

jacking up the support posts

repairing the support posts

replacing the fieldstone foundation

The sill was supported with fieldstones; pretty typical for construction this old, but not exactly what I want to support the new sill and repaired posts. Some were small enough to muscle out of there, others, not so much. Some were also tucked halfway under the asphalt as well.